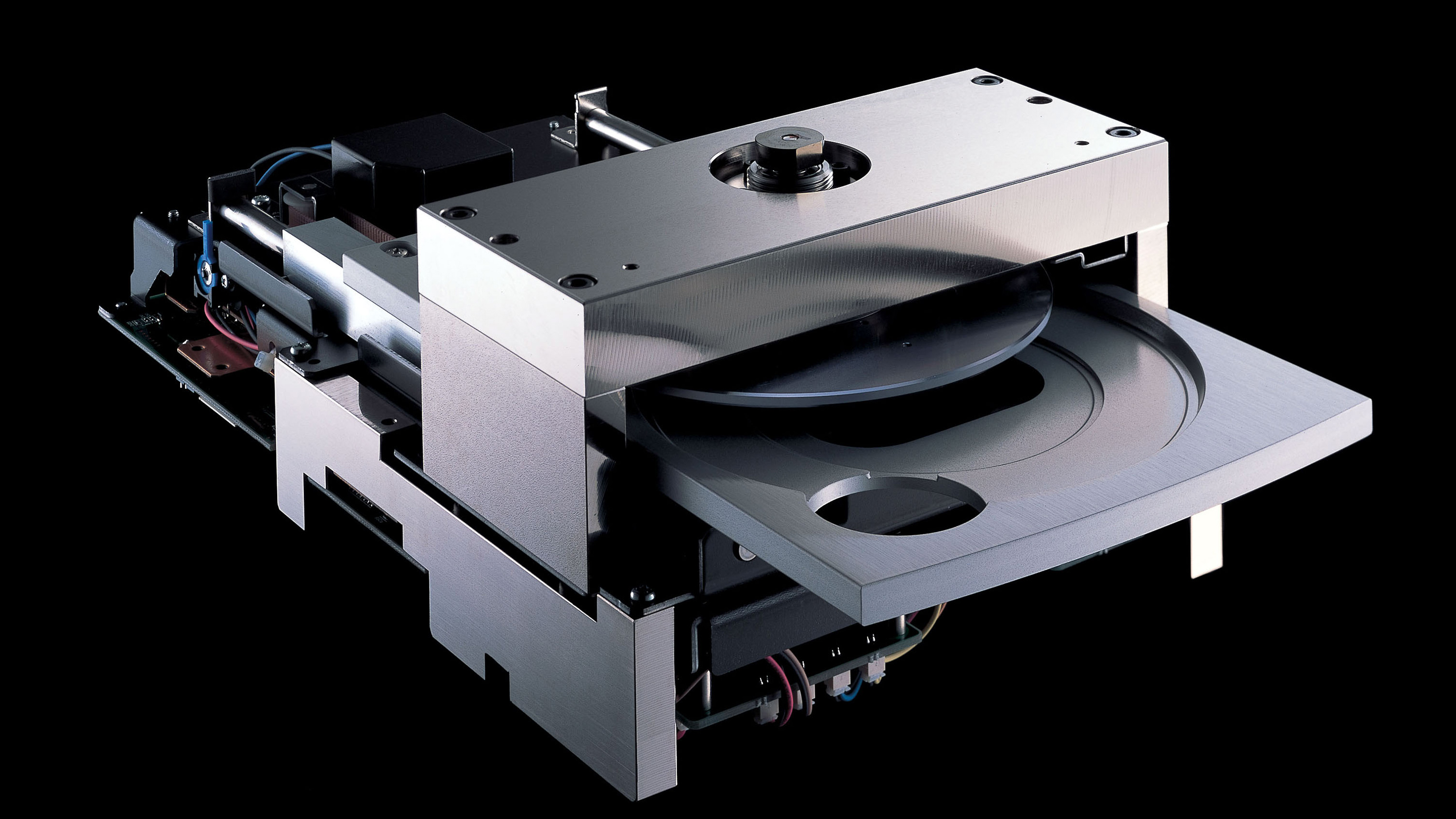

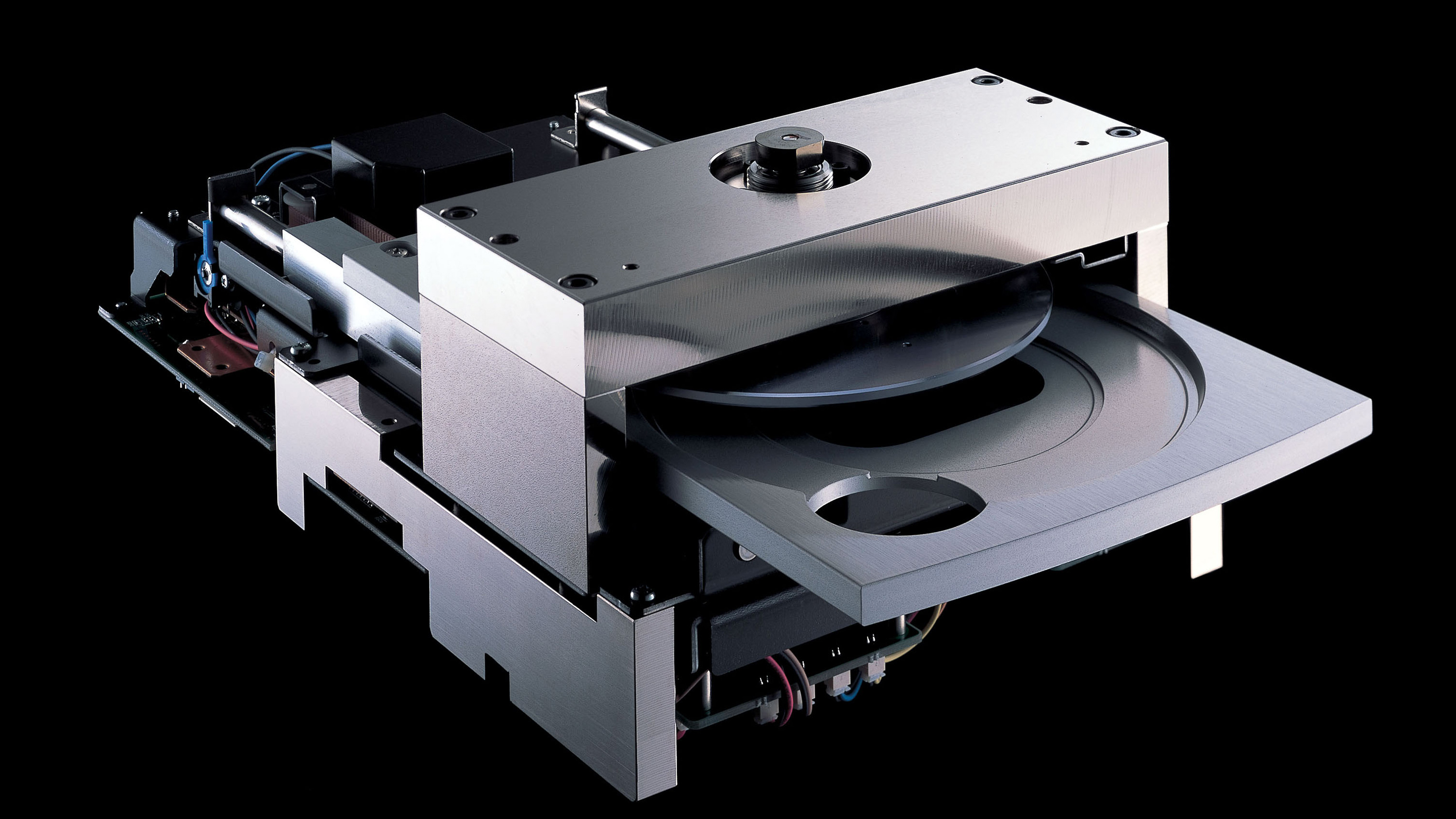

Ultra-high-precision turntable system---VRDS-NEO Mechanism

When an SA-CD or DVD disc is played, the higher-speed rotation causes increased and unwanted vibrations. These vibrations cause the disc surface to shake, making it difficult for the laser pick-up to read the data accurately. The VRDS turntable is designed to physically correct all vibrations and completely stabilize the disc so adverse effects during high-speed rotation can be eliminated.

High-speed rotation also necessitates that the spindle shaft be more robust than in the past. The turntable, which is considered the heart of the VRDS mechanism, is supported by highly precise and extremely rigid mechanical components.

Coreless motor with no rotational irregularities

X-03SE/UX-3SE uses a long-life three-phase brushless spindle motor which has developed for the X-01/UX-1 and the flagship model P-01 for high-speed turntable rotation. Development of the magnetic circuit, consisting of a coil mounted on the 10mm-thick precisely cut steel bridge and a turntable-mounted neodymium magnet was completed through numerous tests and scientific validations, including magnetic field analysis. The optimized magnetic circuit minimizes rotation irregularities in the motor and makes it possible to reduce fluctuations in the motor drive current, thereby lessening any effects on audio circuits and other areas.

Newly designed duralumin turntable

During SA-CD or DVD playback, the maximum rotation speed is 4.5 times greater than the rotation speed during conventional CD playback. In order to ensure that the turntable could handle this high-speed rotation, ESOTERIC selected duralumin as the turntable material. This material is best known as the body material used in aircraft. ESOTERIC has developed new technology for processing this material into lower mass with higher precision. As a result, X-03SE/UX-3SE enables smooth turntable response and stable data acquisition properties by preventing disc vibration. The turntable is dyed a black color in order to absorb any diffused reflection of the laser from the pick-up.

Rigidity and precision are significantly improved by the use of

highly precise ball bearings used in the spindle shaft assembly

A pair of precise ball bearings is used in the spindle shaft bearing unit and a pre-load is applied to the bearing inner rings to significantly reduce rattling and shaft movement during use. This dramatically increases the precision of the bearing unit and greatly improves rotational and positioning accuracy.

Advanced pick up technology --- thread servo section

ESOTERIC developed an ingenious component structure for driving the pickup lens and a new sled structure to move the pickup unit with an extremely high level of accuracy. This new system ensures that the laser optical axis is always positioned at the very center of the pit track for optimal reading.

These modifications to earlier VRDS mechanisms (P-01) make it possible to minimize the adverse effects of disc surface shaking and eccentricity at higher rotational speeds.

Pickup structure designed to prevent laser optical axis tilting during lens movement

The pickup in ordinary players is designed so that the lens hangs from a wire. This design is not only low in rigidity, but allows the laser optical axis to tilt away from a vertical orientation as the lens moves. In contrast, the pickup used in the X-03/UX-3 has a sliding-shaft structure that prevents the laser optical axis from tilting even when the lens is moved. ESOTERIC has also increased the rigidity of the parts supporting the lens.

(pickup structural drawing)

Equipped with a TEAC proprietary hall element sensing-type three-phase brushless motor. Speed feedback-controlled sled transport with superior response and minimal extraneous pickup lens movement

In order to provide a very high-performance pickup capable of smooth, continuous movement, a proprietary hall element sensing-type three-phase brushless motor is used in the sled transport, and powerful electronic speed feedback circuits control this sled mechanism. The pick-up component is mounted on the thick aluminum die-cast pick-up base for higher tracking ability. This is yet another design feature that improves the precision and accuracy of the data acquisition functions.

Vibration isolation for spindle motor system and sled moving system

The spindle system, which may generate fine vibrations during rotation, is isolated from the sled moving system. Since the sled mechanism requires very delicate control, this isolation from high-frequency vibrations ensures superior reading performance.

High-precision mechanism and new software controlled servo control for superior playability

The precision-machined proprietary mechanism combines with new system software to provide optimal servo control for each type of disc. This equates to superior media playability.

Cut aluminum disc tray

The disc tray, which has an influence on sound quality, is processed by cutting the tray from a solid aluminum block. The disc contact side of the tray is coated for disc protection.